WB2-4

Critical current and screening current field of RE123 split wire

Dec.1 13:50-14:05 (Tokyo Time)

Muroran Institute of Technology1

Sumitomo Electric Industries, Ltd.2

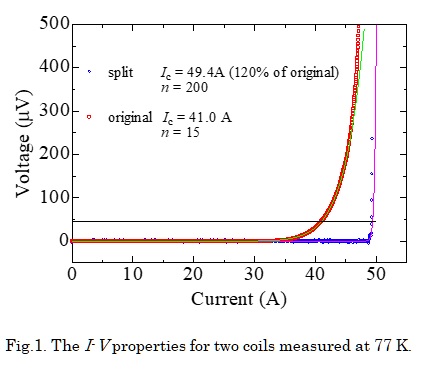

The study of fine filamentation for tape shaped RE123-coated conductors is important to reduce the shielding current and AC loss, for application in high-field magnets. However, the critical current is usually decreased largely. Recently, we proposed a method of inner split to keep or increase the critical current of the coated conductor [1-2]. We reported the properties of split wires fabricated with tear stress along width direction of the wire, then the splits were formed along longitudinal direction of the coated conductor. In this study, several samples were prepared with different applied stress and split numbers. In measurement results, few samples almost keep the original critical current. We also prepared two coils each winded by original coated conductor and split wire. The same specification was chosen in the coils, with wire length of 4.6 m, inner diameter 30, and length of coil 80 mm. With criterion of critical current 0.1μV/cm, the critical current of coil winded by split wire was increased about 20% than that winded by original wire in the magnetic field of coil at 77 K, and the n value was largely increased to 200 from that of original of 15, as seen in Fig. 1. The fabrication method and the properties of split wire and coil will be discussed in upcoming ISS2020.

[1] Xinzhe Jin, Hidetoshi Oguro, Yugo Oshima, Tetsuro Matsuda and Hideaki Maeda, "Development of a REBa2Cu3O7-δ multi-core superconductor with “inner split” technology," Superconductor Science and Technology 29 (2016) 045006 (8pp)

Keywords: coated conductor, RE123, split, critical current