AP-3-3

Performance test results of mid-scale REBCO coil for 33 T cryogen-free superconducting magnet

17:15-17:30 28/11/2023

*Satoshi Awaji1, Alexandre Zampa1, Arnaud Badel2, Kohki Takahashi1, Tatsunori Okada1, Yuji Tsuchiya1, Gen Nishijima3, Tatsuro Uto4, Hiroyuki Takewa4, Satoshi Hanai4, Shigeru Ioka4, and Junji Inagaki4

1. High Field Laboratory for Superconducting Materials, Institute for Materials Research, Tohoku University, Sendai 980-8577, Japan

2. University of Grenoble Alpes, G2Elab/Néel Institute, CNRS, Grenoble 38042, France.

3. National Institute for Materials Science, Tsukuba 305-0003, Japan.

4. Toshiba Energy System and Solutions Corporation, Yokohama 230-0045, Japan.

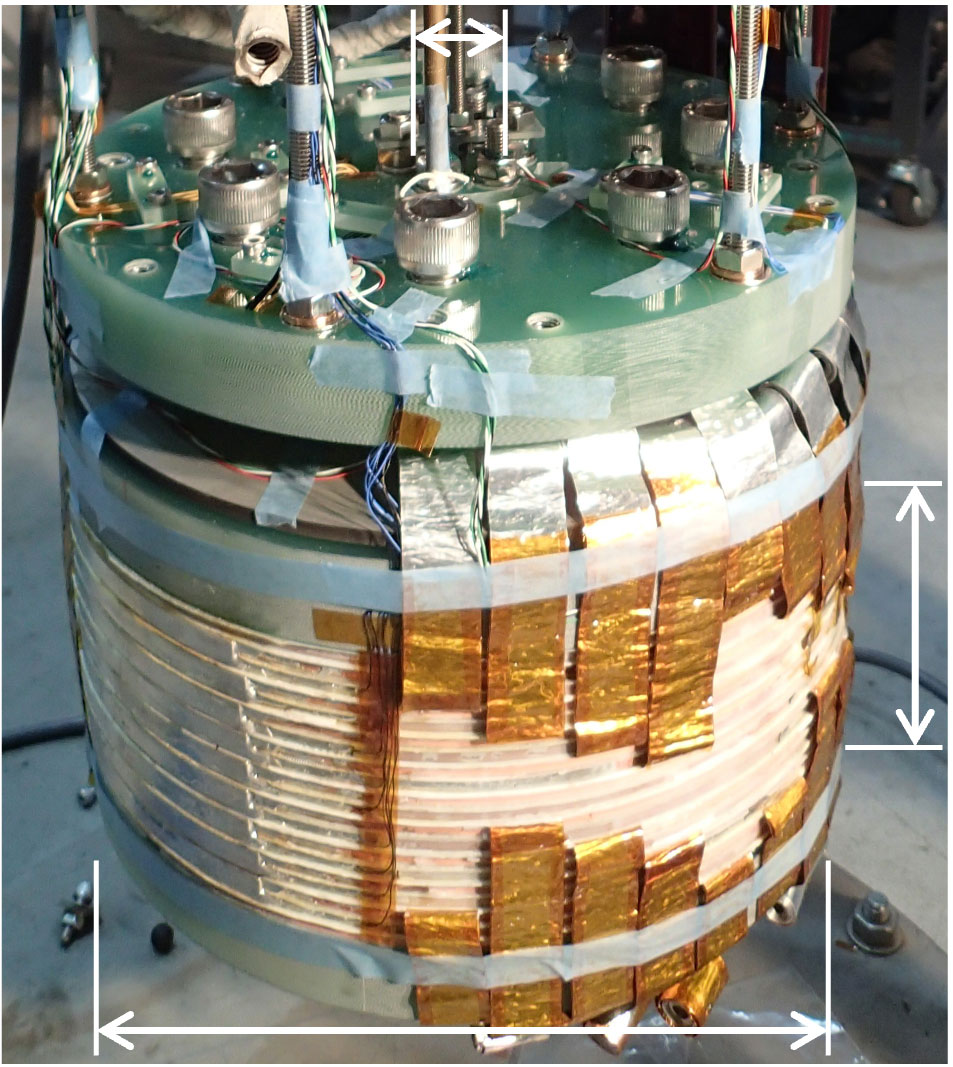

The 25 T cryogen-free superconducting magnet, consisting of a 11 T Bi2223 insert and 14 T Nb3Sn/NbTi Rutherford cable coils, is operated as a user magnet at HFLSM since 2015 [1]. Now a 33 T cryogen-free superconducting magnet project is on-going. For the insert of that project, REBCO High Temperature Superconductor is a strong candidate because of high in-field performances and strong mechanical propensities. However, there are some serious issues such as a local degradation related to a delamination, screening current effects on mechanical stress and magnetic field error, and effective quench detection/protection. We have proposed the “robust REBCO coil concept” to overcome those problems for high field magnets, consisting of two bundle REBCO tape co-winding, all turn separation with fluorine coated polyimide, edge impregnated pancake with a thin FRP plate [2]. We have performed many R&D studies with REBCO small-scale coils and confirmed their good performances under high stress states and high magnetic fields. Then recently we made a mid-scale 20 stacked REBCO pancake coil with “Robust REBCO coil concept”. The height, inner- and outer-diameters of the coil are 101mm, 68 mm and 266 mm, respectively.

We performed tests under a background field of 14 T at 4.2 K in LHe at the National Institute for Materials Science. A total central magnetic field of 25 T were produced with 300 A (11 T being generated by the insert,) without any anomalous voltages. It is found that the magnetic field error has two components, from a screening current in the REBCO tape and a coupling current between two REBCO tapes, which have opposite field contribution. From a mechanical point of view, we could confirm that the maximum stress in the REBCO coil is reduced thanks to the edge impregnation, as it optimizes the stress distribution in the coil [3,4].

We also tested that insert at various temperatures from 20 K to 75 K under conduction cooling conditions. Stable and long-term operations up to 300 A were confirmed at 20 K. The limiting current of the coil, that is the current at which significant dissipation can be observed in steady state, could be reached safely and repeatedly. From 75 K down to 47 K, that limiting current was estimated from 60 A up to 250 A, with an arbitrary criterion of 5 mV. [5] That steady state dissipation was reached without thermal runaway and was distributed over a large portion of the coil, which indicates that there are no significant local defects in the coil. The observed coil performances at various temperatures will be discussed and compared with expectations, as well as the magnetic field error and losses related to a screening current in the tape and a coupling current between tapes.

[1] S. Awaji et al., SuST 30 (2017), 065001

[2] S. Awaji et al., IEEE TAS, 31 (2021) 4300105.

[3] K. Takahashi et al., IEEE TAS, 35 (2023) 4601405

[4] A. Badel et al., IEEE TAS, 35 (2023) 4601505

[5] A. Zampa et al., to be presented at MT28.

This work was supported by JSPS KAKENHI under Grant 18H05248.