AP-4-3-INV

Removal of Microplastic Fibers Using Magnetic Force and Swirling Flow

18:45-19:15 28/11/2023

*Yoko Akiyama, Satoshi Fujii, Yuichiro Manabe, Fuminobu Sato

Graduate School of Engineering, Osaka University 2-1 Yamadaoka, Suita, Osaka 565-0871, Japan

1. Introduction

The impact on the ecosystems of microplastic fibers (MPFs) released into the environment is one of the most serious issues. MPFs are found in laundry wastewater. There is a concern that MPFs may pass through wastewater treatment plants and affect the ecosystem through the absorption of toxic substances and their uptake by living organisms [1].

We have investigated a method of attaching ferromagnetic magnetite to MPFs, which is called “magnetic seeding”, and removing them by magnetic force. Our previous beaker-scale experiments successfully removed 90-97% of particulate and debris microplastics [2]. However, in the continuous high gradient magnetic separation (HGMS) systems, the magnetic force applied to magnetite particle exceeds the adhesion force between the MPFs and magnetite, causing the magnetite to desorb from the MPFs. In addition, a challenge unique to HGMS is the need for periodic cleaning of the magnetic filter.

To solve these problems, a magnetic separation system using magnetic force and a swirling flow was developed to separate MPFs as a maintenance-free continuous magnetic separation process. This is a novel magnetic separation method in which the centrifugal force from the swirling flow is assisted by a magnetic field that induces the ferromagnetic materials to be guided to the outside and concentrates the magnetically seeded MPFs. In this study, the applicability of the proposed method to the removal of MPFs was verified through simulations and experiments using a laboratory-scale apparatus.

2. Experimental Methods

Magnetite (primary particle size: 0.5 µm) was added to distilled water at a weight ratio of 1000:1 and sonicated for 10 min. MPFs (polyester, 400 µm in length and 10.1 µm in diameter) were separately added to distilled water, to which the magnetite suspension described above was added. The mixture was then stirred with a stirring blade at 100 rpm for 30 minutes to produce a simulated effluent containing magnetically seeded MPFs (MPFs concentration 10 mg/L, magnetite concentration of 10 mg/L).

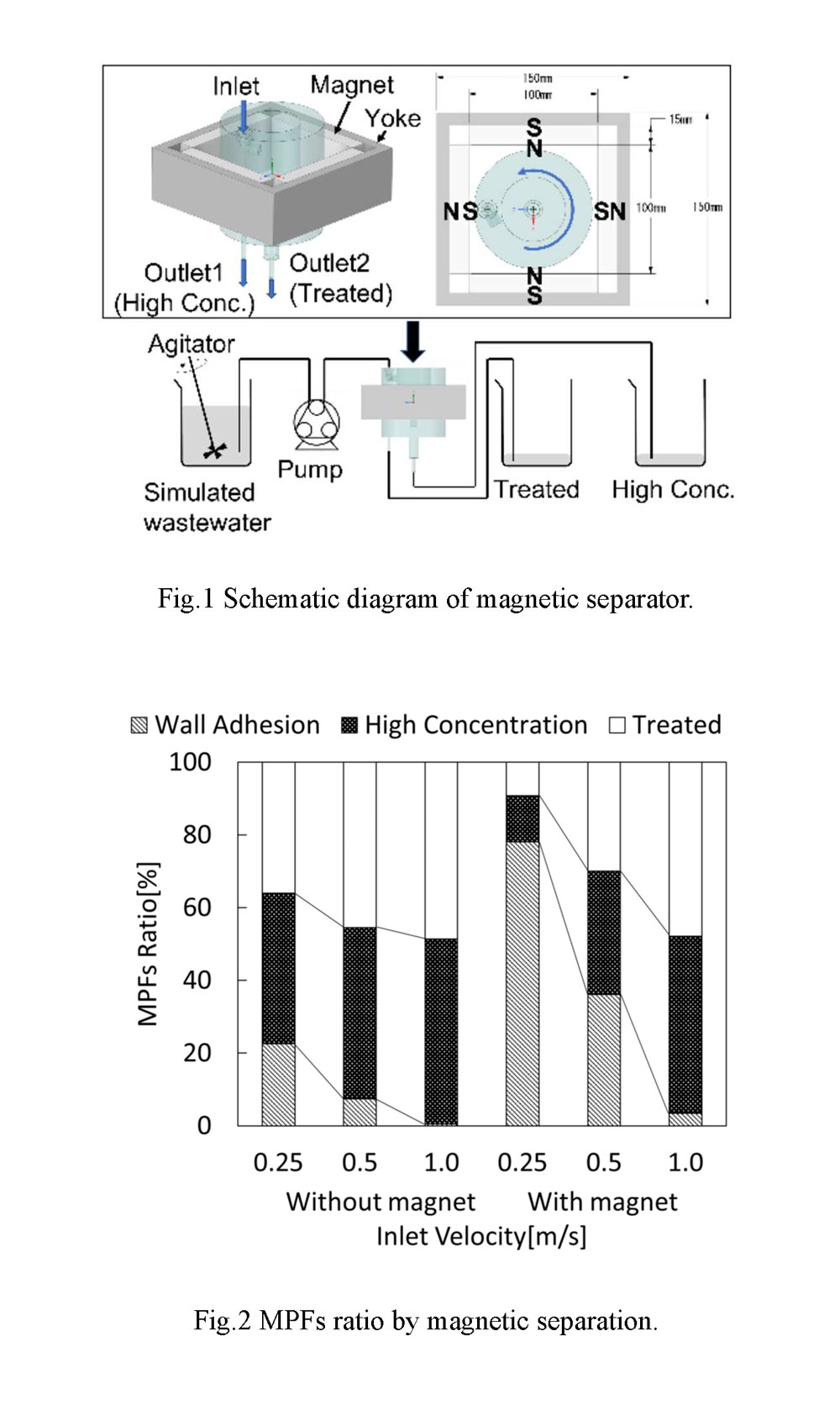

A schematic diagram of a magnetic separator using a swirling flow is shown in Fig. 1. The magnetic separator is designed to generate a swirling flow in the channel that exerts an outward centrifugal force on the MPFs, and also to exert an outward magnetic force on the magnetically seeded MPFs with a quadrupole opposing neodymium magnet (maximum 0.4 T at the inner wall of the channel and 0.0 T at the center) placed outside the channel. The design allows the magnetic force to act outward on the magnetically seeded MPFs. The magnetic separation performance was investigated by varying the inlet flow velocity to 0.25, 0.5, and 1.0 m/s and collecting the effluent from the outside and inside of the channel separately as Outlets 1 (treated water) and 2 (concentrated water).

3. Results and Discussion

Fig. 2 shows the changes in the distribution ratio of MPFs into concentrated water, treated water, and wall adhesion by magnetic separation with and without a magnetic field and inlet flow velocity. Compared with the case without and with magnetic field, the ratio of MPFs in the concentrated water decreased with the application of magnetic field, but the rate of wall adhesion increased, especially at low flow velocities. In addition, the number of MPFs adhering to the wall decreased with increasing inlet flow velocity. This is thought to be due to the increase in flow velocity near the wall caused by the increase in inlet flow velocity and the decrease in the passage time (magnetic field application time) of the MPFs through the channel. It was also confirmed that MPFs adhering to the wall can be easily recovered by removing the magnet from the flow path. Therefore, it is assumed that approximately 70% and 90% of MPFs can be recovered at inlet flow velocities of 0.5 m/s and 0.25 m/s, respectively, which is the sum of the ratio of the adhesion rate to the wall surface and that in the concentrated water. Particle trajectory simulations considering the velocity in a swirling flow and magnetic field distributions showed a similar trend to the experiment, supporting the above discussion.

4. Conclusion

The magnetic separation of magnetically seeded MPFs was investigated using a magnetic field and swirling flow. The results showed that the MPFs could be guided outward by magnetically assisting the swirling flow. It was also shown that the removal performance can be controlled by the inlet flow velocity. However, many MPFs adhered to the inner wall of the channel, requiring frequent cleaning and preventing the separation system from being maintenance-free. Therefore, further improvement of the separation mechanism is needed to minimize the adhering MPFs. In the future, we aim to scale up the system by using opposing bulk magnets.

[1] J J. Sun, et al. : Water Research, Vol. 152 (2019) pp. 21-37

[2] R. Ueda, et al. : Progress in Superconductivity and Cryogenics, Vol. 24, Issue 3 (2022) pp.12-18

Part of this study is supported by JSPS KAKENHI Grant Number 23H03575.