PL-3

Progress in Cable-based High Performance Superconducting Magnets for SPARC

09:45-10:30 29/11/2023

*Brandon Sorbom, Elle Allen, Erica Salazar, Charlie Sanabria, Chris Craighill, Rui Diaz-Pacheco, Ben Weinreb, Justin Nealey, Eric Laamanen, Elizabeth Brownell, Keshav Vasudeva, Dan Nash, Owen Duke, Ashleigh Francis, Annie Hughes, Ronak Padukone, Alex Warner, Nick Goumas, Julio Colque, Nick Kotsifakis, Carl Avola, Richard LeBlanc, Andrei Shylo, Aliya Greenberg, Rui Vieira, Amanda Hubbard, Ted Golfinopoulos, Amy Watterson, Phil Michael, Nicolo Riva, Rod Badcock, Mike Davies, Bart Ludbrook, Dominic Moseley, Shahna Muhammad Haneef

Commonwealth Fusion Systems, 117 Hostpital Road, Devens MA 01434, USA

MIT, 77 Massachusetts Ave, Cambridge, MA 02139, USA

Paihau Robinson Research Institute, 69 Gracefield Road, Gracefield, Lower Hutt 5010, New Zealand

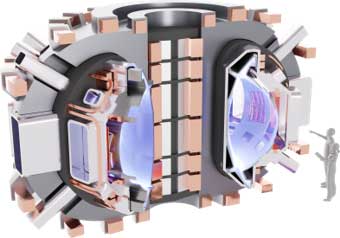

The key performance metrics in magnetically-confined fusion devices called tokamaks scale as the strength of the Toroidal Field (TF) magnets to the fourth power. One of the most important consequences of these scalings is that increasing the magnetic field in a tokamak enables a much smaller device to demonstrate net-energy production, leading to dramatic reductions in cost, timeline, and organizational complexity required to construct and operate the fusion device. Following the demonstration of a large-bore, 20 T, steady-state, REBCO magnet in September 2021, an energy-breakeven fusion device called SPARC has begun construction in Devens, MA. In addition to the high-field steady-state TF coils, SPARC will be a pulsed tokamak with superconducting Central Solenoid (CS) and Poloidal Field (PF) Coils having peak fields up to 24 T and ramp rates as high as 5 T/s. To enable these demanding conditions, CFS, in collaboration with MIT and PRRI, has matured a novel, low AC loss, REBCO HTS cable called PIT VIPER. These cables have been derisked for AC losses, IxB loading, transverse compression, joint performance, insulation fatigue life, quench detection, and fabrication. This program will culminate in the fabrication and testing of a four-layer demonstration coil (Central Solenoid Model Coil, or CSMC) using PIT VIPER cables to fully demonstrate the manufacturability and performance required for SPARC CS and PF coils. This presentation will show the PIT VIPER de-risking R & D and the progress made on the CSMC project to date.

This work has been funded by Commonwealth Fusion Systems and has been supported by the ARPA-E BETHE program of the US Department of Energy