WB-1-5

Enhancement mechanism of uniaxial electro-mechanical behaviors in second-generation high-temperature superconducting tapes

11:15-11:30 28/11/2023

Chunjiang Guo a, Yue Wu a, Wei Wu a, Zili Zhang c, Jiangtao Shi a, Sikan Chen b, Jiamin Zhu b, Yawei Wang a, Zhijian Jin a, Qiuliang Wang c and *Yue Zhao a

a. School of Electronic Information and Electrical Engineering, Shanghai Jiao Tong University, Shanghai 200240, People’s Republic of China

b. Shanghai Superconductor Technology Co., Ltd, Shanghai 201203, People’s Republic of China

c. Institute of Electrical Engineering, Chinese Academy of Sciences, Beijing 100190, China

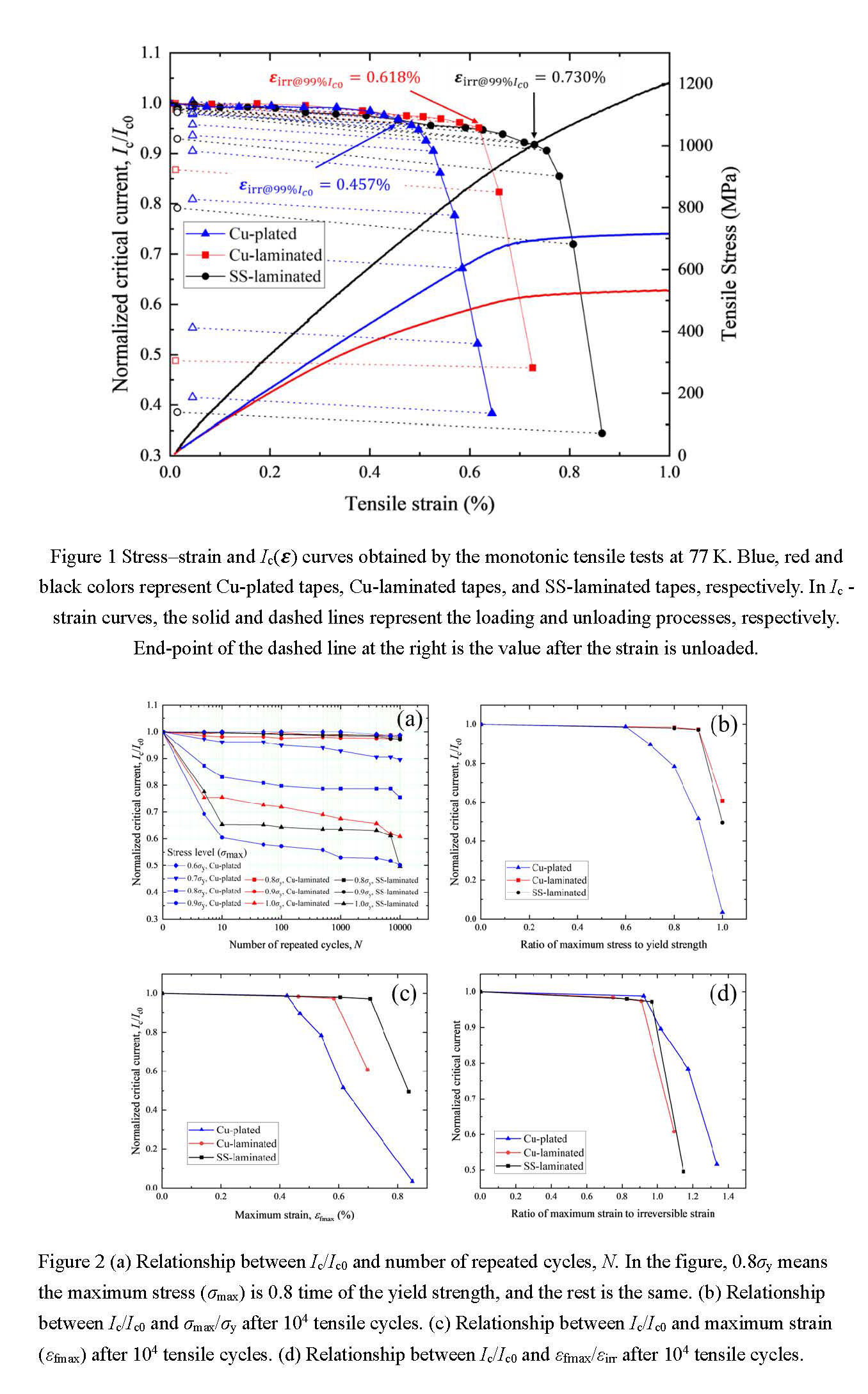

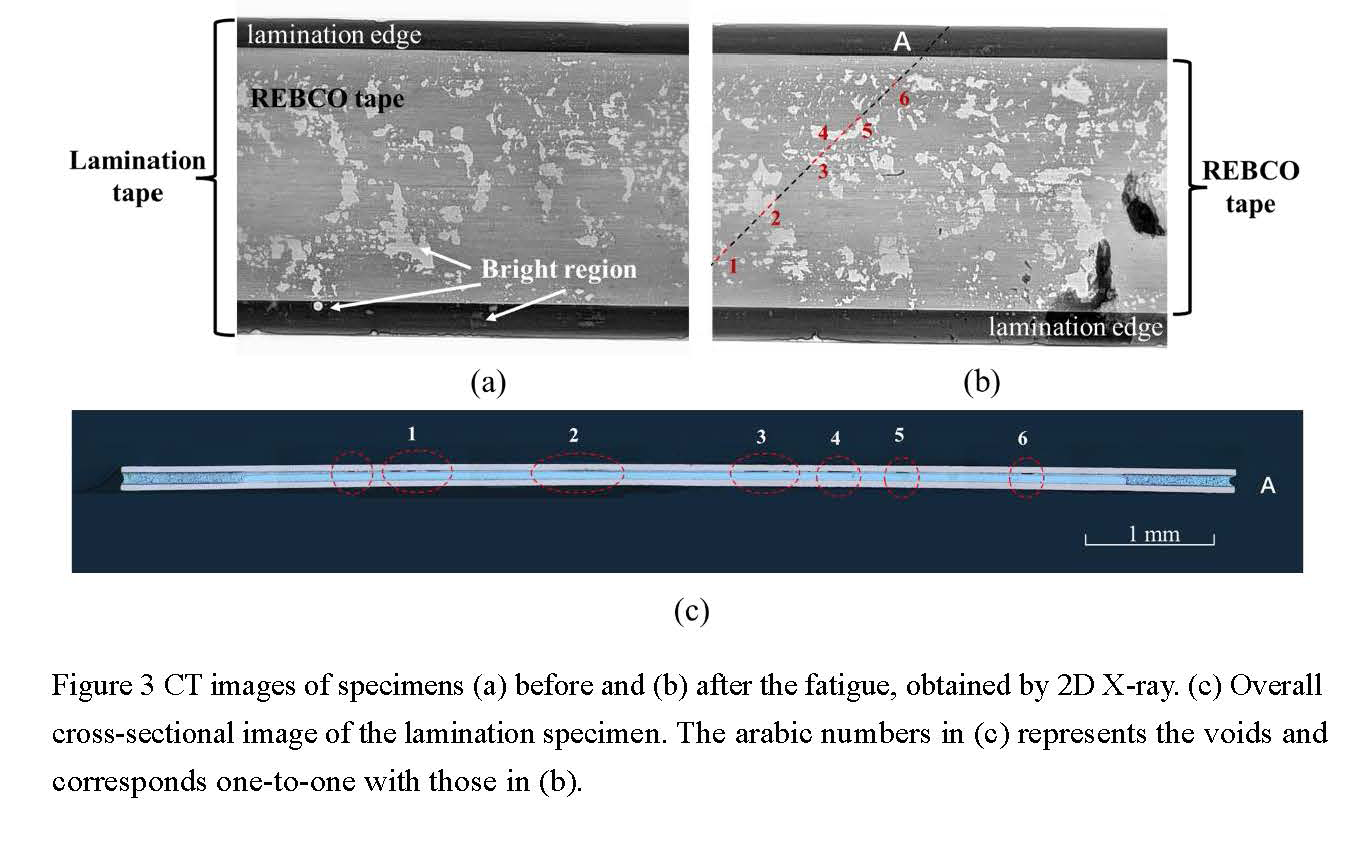

The second-generation high-temperature superconducting (2G-HTS) tapes are subjected to complex stress/strain in practical applications. For the complex operation conditions, lamination techniques are widely used to improve the robustness of tapes. However, lamination makes the 2G-HTS tape structure more complicated, which can significantly affect their electro-mechanical behaviors. In this work, uniaxial monotonic tensile tests were performed to obtain the stress-strain relationship and the strain dependence of critical current (Ic(ε)) in liquid nitrogen conditions. Two types of laminated 2G-HTS tapes (copper-laminated and stainless steel-laminated) were compared with copper-plated 2G-HTS tapes. The results showed that the irreversible tensile strains of Cu-laminated and SS-laminated tapes were much higher than that of Cu-plated tapes, which increased by ~35% and ~60%, respectively. High consistency between the experimental and theoretical Ic values in 2G-HTS tapes under tensile strain was verified by the Ic(ε) model. Based on the residual strain (εres) calculation of composite multilayer structures, we confirmed that it was mainly due to the increase of the compressive residual strain of superconducting layers. Further, tensile fatigue tests also confirmed the significant improvement of the tensile fatigue electro-mechanical behaviors in the laminated 2G-HTS tapes. Finally, 2D X-ray and SEM cooperative analysis were used to characterize the tape microstructure before and after fatigue, and the correlation between micro-defects and non-destructive imaging features was established. It was found that the internal solder layer and its interface were seriously damaged to release the stress.

This work provides a strategy to improve the electro-mechanical behaviors of 2G-HTS tapes by adjusting the composite structure to change residual strain.

[1] H.S. Shin, A. Gorospe, Z. Bautista, M.J. Dedicatoria, Evaluation of the electromechanical properties in GdBCO coated conductor tapes under low cyclic loading and bending, Supercond Sci Technol. 29 (2016). https://doi.org/10.1088/0953-2048/29/1/014001.

[2] Y. Zhao, J.M. Zhu, G.Y. Jiang, C.S. Chen, W. Wu, Z.W. Zhang, S.K. Chen, Y.M. Hong, Z.Y. Hong, Z.J. Jin, Y. Yamada, Progress in fabrication of second generation high temperature superconducting tape at Shanghai Superconductor Technology, Supercond Sci Technol. 32 (2019). https://doi.org/10.1088/1361-6668/aafea5.

[3] P. Gao, M. Guan, X. Wang, Y. Zhou, Electromagnetic-thermal-structure multi-layer nonlinear elastoplastic modelling study on epoxy-impregnated REBCO pancake coils in high-field magnets, Superconductivity. 1 (2022) 100002. https://doi.org/10.1016/j.supcon.2022.100002.

[4] H.S. Shin, M.B. De Leon, M.A.E. Diaz, Investigation of the electromechanical behaviors in Cu-stabilized GdBCO coated conductor tapes using high-cycle fatigue tests at 77 K and related fractographic observations, Supercond Sci Technol. 33 (2020). https://doi.org/10.1088/1361-6668/ab617b.

[5] S. Hahn, K. Kim, K. Kim, X. Hu, T. Painter, I. Dixon, S. Kim, K.R. Bhattarai, S. Noguchi, J. Jaroszynski, D.C. Larbalestier, 45.5-tesla direct-current magnetic field generated with a high-temperature superconducting magnet, Nature. 570 (2019) 496–499. https://doi.org/10.1038/s41586-019-1293-1.

[6] J. Zhu, Y. Zhao, S. Chen, S. Zhen, C. Zhang, B. Song, J. Sheng, W. Wu, Z. Jin, Lamination process of second generation high temperature superconducting tape at Shanghai Superconductor Technology, Mater Today Commun. 31 (2022). https://doi.org/10.1016/j.mtcomm.2022.103721.

[7] H.S. Shin, Z. Bautista, Establishing a test procedure for evaluating the electromechanical properties of practical REBCO coated conductor tapes by the uniaxial tension test at 77 K, Supercond Sci Technol. 32 (2019). https://doi.org/10.1088/1361-6668/ab0309.

[8] P. Gao, W.K. Chan, X. Wang, Y. Zhou, J. Schwartz, Stress, strain and electromechanical analyses of (RE)Ba2Cu3O x conductors using three-dimensional/two-dimensional mixed-dimensional modeling: Fabrication, cooling and tensile behavior, Supercond Sci Technol. 33 (2020). https://doi.org/10.1088/1361-6668/ab7778.

[9] P. Gao, J. Mao, J. Chen, X. Wang, Y. Zhou, Electromechanical degradation of REBCO coated conductor tapes under combined tension and torsion loading, Int J Mech Sci. 223 (2022). https://doi.org/10.1016/j.ijmecsci.2022.107314.

[10] Y. Pan, P. Gao, Analysis of mechanical behavior and electromechanical properties of REBCO-coated conductor tapes under combined bending-tension loads using numerical methods, Supercond Sci Technol. 36 (2023). https://doi.org/10.1088/1361-6668/acbac7.

[11] K. Osamura, M. Sugano, S. MacHiya, H. Adachi, S. Ochiai, M. Sato, Internal residual strain and critical current maximum of a surrounded Cu stabilized YBCO coated conductor, Supercond Sci Technol. 22 (2009). https://doi.org/10.1088/0953-2048/22/6/065001.

[12] K. Ilin, K.A. Yagotintsev, C. Zhou, P. Gao, J. Kosse, S.J. Otten, W.A.J. Wessel, T.J. Haugan, D.C. Van Der Laan, A. Nijhuis, Experiments and FE modeling of stress-strain state in ReBCO tape under tensile, torsional and transverse load, Supercond Sci Technol. 28 (2015). https://doi.org/10.1088/0953-2048/28/5/055006.

[13] X. Pan, W. Wu, X. Yu, L. Lu, C. Guo, Y. Zhao, Typical electrical, mechanical, electromechanical characteristics of copper-encapsulated REBCO tapes after processing in temperature under 250 °C, Supercond Sci Technol. 36 (2023). https://doi.org/10.1088/1361-6668/acb740.

This work was financially supported by the National Key R&D Program of China of National Natural Science Foundation of China (Grant No. 2022YFE03150201), the National Natural Science Foundation of China (Grant No.52277027), and Scientific Research Program of Science and Technology commission of Shanghai Municipality (Grant No. 21XD1430700). The authors would like to acknowledge the instrumental analysis center (IAC) of Shanghai Jiao Tong University for specimen preparation and structural characterization.