WB-3-1-INV

High-performance Double-sided REBCO Tapes

15:00-15:30 28/11/2023

*Venkat Selvamanickam1, B. Sarangi1, J. Sai Sandra1, M. Paidpilli1, C. Goel1, Y. Li1, E. Galstyan2, G. Majkic1

1. Department of Mechanical Engineering, Advanced Manufacturing Institute, Texas Center for Superconductivity, University of Houston, Houston, TX 77204, USA

2. AMPeers LLC, Houston, TX 77059, USA

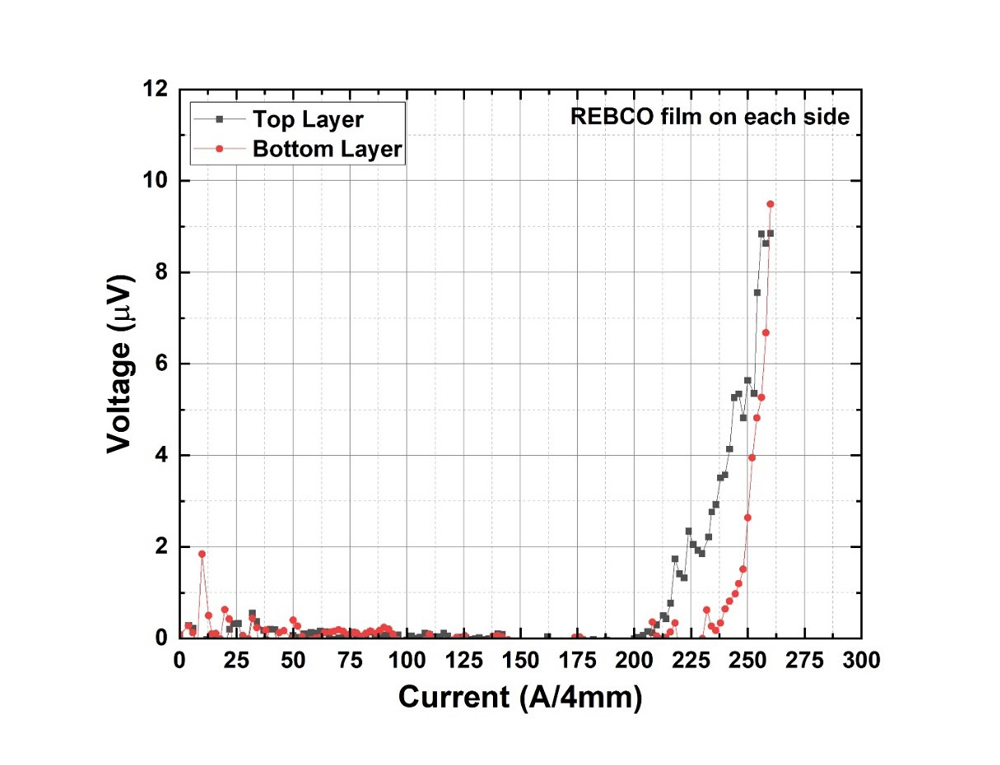

For most HTS applications to be commercially-competitive with conventional technologies, the HTS conductor cost has to be in the range of $10/kA-m. The best option for an order-of-magnitude reduction in cost is to increase the critical current (Ic). Previously, we had demonstrated REBCO tapes using Advanced Metal Organic Chemical Vapor Deposition (A-MOCVD) with up to 5x the Ic of industrial tapes. In order to achieve even higher Ic as well reduce unit cost ($/m), we have developed double-sided REBCO tapes wherein both sides of the tape are simultaneously coated with REBCO film in a single step by A-MOCVD [1]. In addition to doubling the Ic, double-sided tapes lead to very efficient use of expensive metal organic precursors, contributing to significant cost reduction. Furthermore, double-sided REBCO tapes always enable face-to-face joints which have 10x lower resistivity than face-to-back joints made with single-sided tapes. Such low contact resistivity also facilitates excellent current sharing between adjacent tapes. The latest results on the electrical and mechanical properties of double-sided REBCO tapes will be presented.

1. M. Paidpilli, J. Sai Sandra, B. Sarangi, C. Goel, E. Galstyan, G. Majkic, V. Selvamanickam, “High-Current, Double-Sided REBCO Tapes by Advanced MOCVD” Supercond. Sci. Technol. 36, 095016 (2023)

This work was funded by award DE-AR0001374 from the Advanced Research Projects Agency – Energy (ARPA-E) and STTR award N68335-21-C-0525 from the Naval Air Systems Command (NAVSEA) through AMPeers LLC.