AP1-4

Behaviors of a No-Insulation HTS - WISE Layer - wound Solenoid Coil in Overcurrent Condition

Dec.1 11:35-11:55 (Tokyo Time)

The Graduate University for Advanced Studies, SOKENDAI1

National Institute for Fusion Science2

We have investigated the High-Temperature Superconducting (HTS) coil winding method “Wound and Impregnated Elastic tapes” (WISE, [1]) for manufacturing HTS helical heliotron magnets. In the HTS-WISE winding concept, a stack of HTS tapes is bundled by a flexible metal tube and the coil winding is performed by utilizing its flexibility. A low-melting point metal then impregnates the winding package. The feasibility as a magnet was reported in [2], where the sample was a No-Insulation (NI) solenoid coil that has mean winding diameter of ~80 mm, the height of ~80 mm and 21.5 turns with layer-winding.

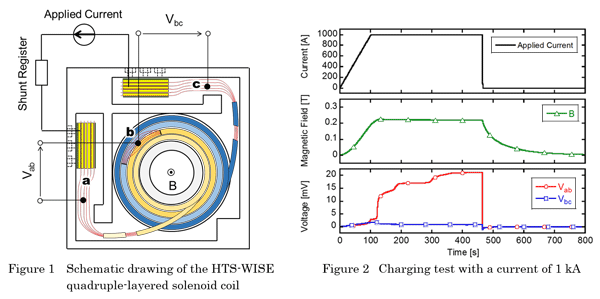

To investigate the fundamental characteristics of HTS-WISE conductors and magnets, the new HTS-WISE solenoid coil (Figure 1) was fabricated and tested. The coil conductor length was 18 m, which was composed of ten HTS tapes and a flexible metal tube. The cable was continuously wound in the quadruple-layered. The diameter and the height were about 100 mm each. current of 1 kA was applied to the solenoid coil and produces the magnetic field more than 0.2 T at the center. The test was performed in liquid nitrogen bath at the temperature of 77 K. The charging test result is shown in Figure 2. A The complicated behavior of the voltage and the magnetic field were observed when the current ramped up, which is considered due to the growth of the local hot spots. When a constant current of 1kA was applied, the voltage and magnetic field showed the temporal change. However, the quenching was not observed for at least 10 minutes. In the presentation, the experimental results and the discussions on the overcurrent behaviors of the HTS-WISE solenoid coil will be shown.

[1] J. Miyazawa et al., Japanese Patent, No. 6749541, 2017

[2] S. Matsunaga et al., IEEE Trans. Appl. Supercond., vol. 30, no. 4, Art. No. 4601405, 2020

Keywords: HTS coils, No-Insulation coils, HTS-WISE conductor and magnet