WB3-5

Inkjet Printing Methodology as a Chemical Solution Deposition approach to high temperature superconducting YBa2Cu3O7−x thick layers

Dec.1 17:00-17:15 (Tokyo Time)

Institut de Ciències de Materials de Barcelona (ICMAB), CSIC, Campus de la UAB, 08193 Bellaterra, Barcelona, Spain1

Universitat Autonoma de Barcelona (UAB), Campus de la UAB, 08193 Bellaterra, Barcelona, Spain2

GRMT, Dept. of Physics, Universitat de Girona, Campus Montilivi, Edif. PII, E17071 Girona, Spain3

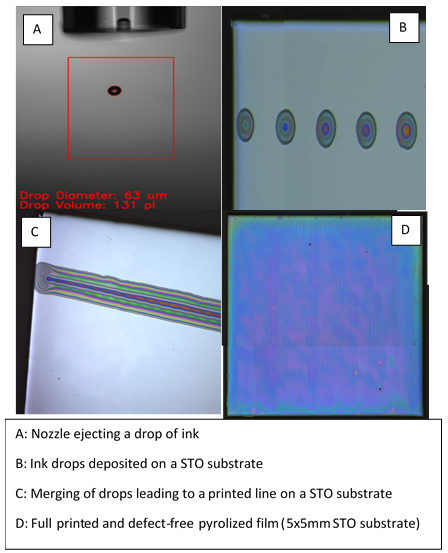

YBa2Cu3O7−x (YBCO) is a promising material for its use in the production and distribution of renewable energies. However, the main issues regarding the manufacturing of superconductors are the production costs. Thus, the search for low cost procedures is mandatory. Printed Electronics have emerged on the last decades with strong potential, like Inkjet Printing (IJP) deposition. This is a Chemical Solution Deposition (CSD) method with a wide range of applications, which relies on the deposition of chemical solutions in the form of drops in the range of picolitres (pL) enabling predefined patterning.

ICMAB-CSIC has developed IJP schemes for CSD TFA-based YBCO layers for long time and reached very relevant results [1, 2]. We could conclude that the TFA-bonds had a very prominent role on the crack-free pyrolysis of the 1 µm thick films. Here, a novel drop-on-demand IJP deposition methodology for the preparation of flour-free (FF) YBCO films is presented. The advantage relies on the high throughput advantages of the FF precursors if used for TLAG-CSD growth (Transient Liquid Assisted Growth of CSD layers) with ultrafast growth rates of 100 nm/s [3]. The use of different additives and evaporation strategies were needed to obtain homogenous depositions and pyrolyzed layers prior to the TLAG growth. Playing with the different characteristics of the fluor-free solutions such its chemical behaviour, use of additives, control of rheology and concentration (mol/L) it was possible to enhance the thickness of the films. The rheological properties of the solution and its thermogravimetric analysis, such as the decomposition pathways of the precursors, have been analysed using advanced in-situ characterization techniques in order to achieve defect-free homogenous films. The structural and superconducting properties of the layers are also evaluated to achieve good performances.

[1] B. Villarejo, et al, J. Mater. Chem. C, 8, 10266 (2020)

[2] C. Pop, et al SUST 32, 015004 (2019)

[3] L. Soler, et al, Nat. Comm 11, 344 (2020)

Keywords: High Temperature Superconductors (HTS), Chemical Solution Deposition (CSD), Inkjet Priting Technology (IJP), Transient Liquid Assisted Growth (TLAG)