AP6-3-INV

ASCEND: A demonstrator of a cryogenic powertrain for aircraft electrical propulsion

*Alexandre COLLE1, Reda ABDOUH1, Matteo TASSISTO1, Emelie NILSSON1, Ludovic YBANEZ1

- Airbus UpNext1

With the environment constraint that will shape the future of the aircraft industry, Airbus is working on three concepts of zero-emission commercial aircraft. It is aimed to explore various technology pathways and aerodynamic configurations but all concepts have in common the use of hydrogen as a primary source. If this energy is stored in its liquid form at cryogenic temperature, it brings major benefits on electric propulsion systems:

by cooling “conventional” technologies and dramatically increasing electrical propulsion system performance by reducing losses (because resistivity and losses depend on system temperature) and therefore the weight of components.

by using high-temperature superconducting technologies for DC (direct current) distribution components, electric motors to increase performances because of no resistivity, no losses and magnetic behaviour of superconducting materials.

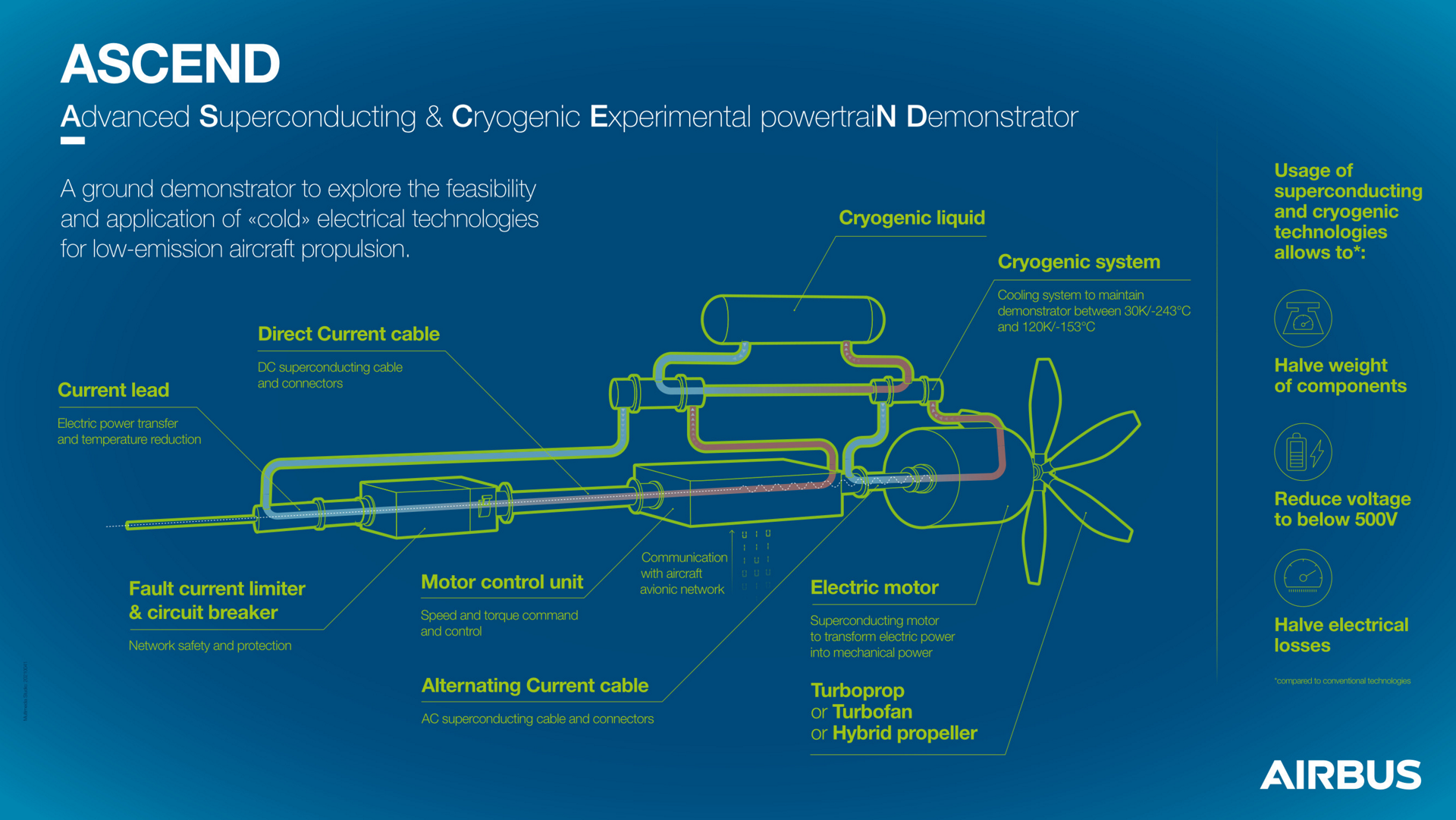

The aim of the ASCEND (Advanced Superconducting and Cryogenic Experimental powertraiN Demonstrator) project, also driven by Airbus over the next three years, is to develop a ground demonstrator of 500kW. The components of this powertrain, shown in Figure 1, are:

A cryogenic electrical protection (superconducting fault current limiter & cryogenic circuit breaker)

An AC and a DC distribution with superconducting cables

A motor control unit with conventional inverter at cryogenic temperatures

A superconducting motor

A cryogenic cooling system with the cryocooler technology for the project (but could be the liquid hydrogen storage in future aircraft)

The review of the components composing the powertrain will be presented with the expected performances that can be obtained with the current technology.

Keywords: Electric Propulsion System, High Temperature Superconductors, Cryogeny