ED2-5

Development of Discrete Type ECT•HTS-SQUID Non-Destructive Evaluation System for Creep Life Assessment of Boiler Tube

*Wenxu Sun1, Yoshimi Hatsukade1, Takao Sugiuchi2, Hidetaka Nishida2

- Faculty of Engineering, Kindai University1

- Energia Economic and Technical Research Institute, The Chugoku Electric Power co., inc.2

Creep life assessment of boiler tubes, such as superheater tubes and reheater tubes in thermal power plants is not established till now. In this study, a discrete type ECT•HTS-SQUID non-destructive evaluation (NDE) system was developed for the characterization of Super304H boiler tubes that are widely used as superheater tubes and reheater tubes under our New Energy and Industrial Technology Development Organization (NEDO) project. Based on our NDE system, creep test specimen tubes under various times at temperature of 700°C and stress of 110 MPa will be inspected indoor for collecting the creep test data for a master curve to predict remaining life. The relationship of defect signal amplitude and void area ratio that are calculated from metallic structure observation at the same time will be investigated in this project. Additionally, this system can also be used outdoor for verification experiments.

In the conventional eddy current testing (ECT), the depth of defect detection is limited by the skin depth of the material under investigation at high frequency around MHz. However, in the discrete type ECT•HTS-SQUID NDE system, low frequency sensitivity of the SQUID gradiometer and the use of ECT coil make it possible to detect even subsurface defects. A double-D excitation coil is used to excite eddy currents in the specimen at room temperature at relatively low frequencies ~2000 Hz, while a planar differential coil is used as a pick-up loop connected with a superconducting input coil that is inductively coupled to the SQUID gradiometer.

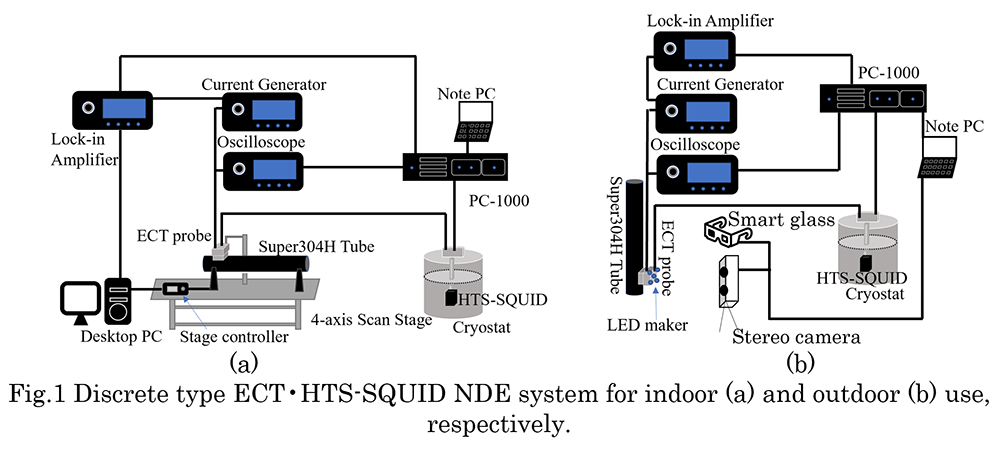

The system can be used for indoor detailed inspection while the ECT probe was set on a precision 4-axis (X-Y-Z-θ) scanner as shown in Fig.1 (a). 550 mm in the axial direction and 360°in the circumferential direction can be inspected at least 0.1 mm scan step around a tube specimen. It can also be used for outdoor while 5 LED makers were set on the ECT probe for position detection by a stereo camera within 300 mm as shown in Fig.1 (b). It can be used for routine inspection in the thermal power plant. Our software developed for the system can not only plot the detected signals with time but can also output a 2-dimeshional (2D) contour map while two LED markers were set at the upper and lower parts of the pipe center to determine the inspection range in axial direction of the tube. The stereo camera can detect the ECT probe within ±40 degrees from the center line in the circumferential direction. In this study, the region within about 100 mm in the axial direction and 35 mm in the circumferential direction of Super304H boiler tubes with diameter of 50.8 mm can be output a 2D contour map with 3~5 mm scan step for identifying the defects. Based on our NDE system, non-destructive inspection will be carried on Super304H creep test specimen tubes that will be under the accelerated aging test with various times till 1,1000 hours.

Keywords: SQUID, non-destructive evaluation, eddy current testing, creep fatigue