WB8-1-INV

Increased superconducting thickness up to 3 micrometer and critical current over than 1000 A in MOD-derived REBaCuO coated conductors

*Chuanbing Cai1,2, Rongtie Huang1, Zhiyong Liu1,2, Jing Chen2

- Shanghai Creative Superconductor Technologies Co., Ltd, Shanghai 201401, China1

- Shanghai Key Laboratory of High Temperature Superconductors, Physics Department, Shanghai University, Shanghai 200444, China2

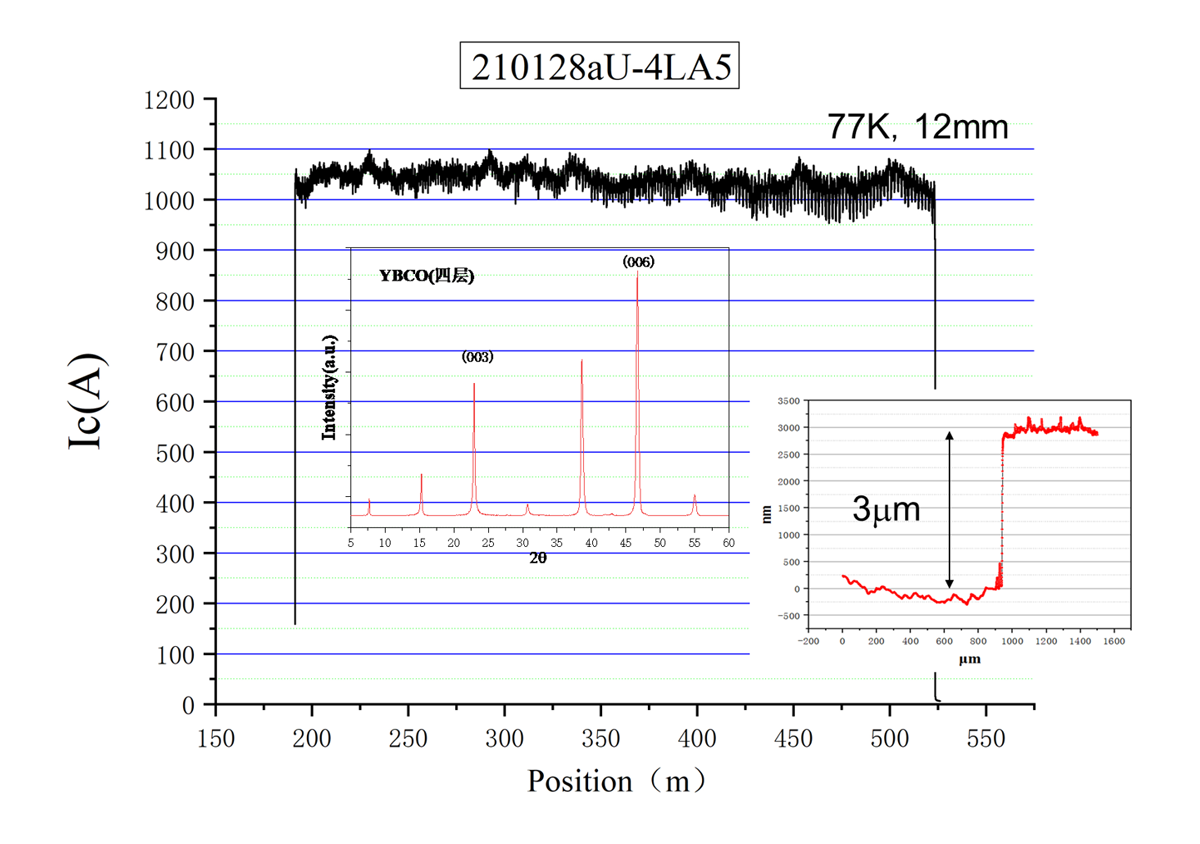

The commercial RE123 tapes are usually manufactured, either by ex-situ techniques, such as metal organic deposition (MOD) and reactive co-evaporation (RCE), or by in-situ techniques, such as pulsed laser deposition (PLD) and metal organic chemical vapor deposition (MOCVD). In case of ex-situ MOD, it is relatively easy to add the rare earth elements or secondary phase particles, as well as the namely thickness by modifying precursor solutions or increasing coating layers. However, it is hard to obtain high critical current (Ic) in namely thick films by simple multiple coating due to thickness-induced degradation of both biaxial textures and critical current density. This leads to effective thickness of RE123 layers is typically limited to be 1-1.5 μm, and then the Ic at 77 K of around 100 ~ 150 A for most of commercially MOD-derived 4 mm-wide tapes. Recently, we develop the novel technique so-called semi-growth, to improve the effective thickness of RE123 films from 1.5 to 3 μm, without degrading biaxial textures and critical current density. Finally, we achieved the critical current around 1 kiloampere at 77 K in MOD-derived RE123 tapes, and realize the reel-to-reel manufacturing as long as 300 meters, giving rise to the Ic at 77 K of around 300 A for commercially available 4 mm-wide tapes.

Figure caption: Critical current along the 300 meter long tape with 3 μm thick RE23 layer, and the left inset shows the XRD pattern with excellent texture, and the right inset shows the thickness profile.

Keywords: RE123 thick films, MOD processing, High critical current