WB9-3

Kinetic control of phase evolution and growth rates of Transient Liquid Assisted Growth of YBCO films

*Silvia Rasi1, Albert Queraltó1, Juri Banchewski1, Lavinia Saltarelli1, Diana Garcia1,3, Adrià Pacheco1, Kapil Kupta1, Susagna Ricart1, Jordi Farjas2, Pere Roura-Grabulosa2, Cristian Mocuta4, Xavier Obradors1, Teresa Puig1

- Institute of Materials Science of Barcelona (ICMAB-CSIC), Spain1

- Universitat de Girona, Spain2

- Universitat Autònoma de Barcelona, Spain3

- Synchrotron SOLEIL, France4

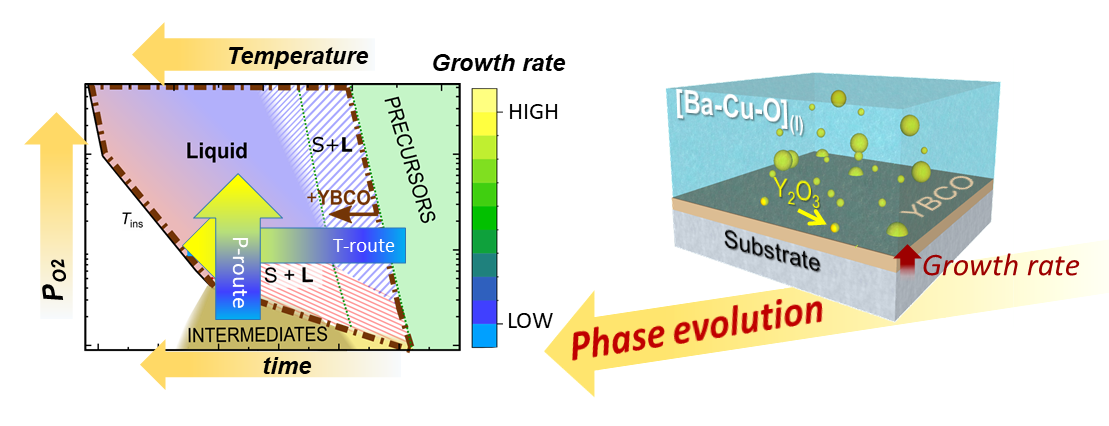

Transient liquid assisted growth (TLAG-CSD) [1, 2] is a novel growth technique for REBa2Cu3O7-x (REBCO, RE=Rear Earth) superconducting films, which combines the advantages of cost-effective chemical solution deposition methods with that of ultra-fast growth rates made possible by liquid-mediated processes. This combination is key to reduce REBCO fabrication costs associated to existing industrial methods. While current efforts with TLAG are focused on transferring the technology to thick films (>500 nm REBCO) and on commercial tapes, there is also a need to advance in the understanding of the main principles of TLAG.

The novelty with respect to other liquid-assisted techniques lies in the transient nature of the barium cuprate liquid induced in TLAG. Controlling the ability to form the transient liquid where REBCO is the stable thermodynamic phase requires a thorough understanding of the kinetic factors governing TLAG-CSD. We have used in-situ synchrotron XRD analysis to determine the kinetic phase diagrams associated to the two TLAG growth routes, the pressure and temperature routes. Special attention is given to the main kinetic factors determining the BaCO3 reaction with the copper oxides and subsequent phase evolution. In addition, we analyze the growth rate mechanisms, the correlation with the process parameters and the conditions to obtain ultra-fast growth rates. We have been able to generate a growth rate diagram from in-situ synchrotron XRD analysis and in-situ resistivity measurements.

[1] Soler, L. et al, Ultrafast transient liquid assisted growth of high current density superconducting films, Nat. Commun. 2020, 11, 344.

[2] Rasi, S. et al, Relevance of the Formation of Intermediate Non-Equilibrium Phases in YBa2Cu3O7–x Film Growth by Transient Liquid-Assisted Growth, J. Phys. Chem. C, 2020, 124 (28), 15574-15584.

Keywords: Transient Liquid Assisted Growth, YBCO growth rate, In-situ synchrotron XRD, Kinetic phase diagrams