WB9-6

Microstructural Characteristics of High Current Density YBCO Superconducting Thin Films Grown by Ultrafast Transient Liquid Assisted Growth (TLAG)

*Kapil Gupta1, Lavinia Saltarelli1, Roger Guzmán1, Albert Queraltó1, Júlia Jareño1, Juri Banchewski1, Laia Soler1, Silvia Rasi1, Diana Garcia1, Valentina Roxana Vlad1, Aiswarya Kethamkuzhi1, Joffre Gutierrez1, Susagna Ricart1, Cristian Mocuta2, Xavier Obradors1, Teresa Puig1

- Institut de Ciència de Materials de Barcelona (ICMAB-CSIC), Spain1

- Synchrotron SOLEIL, L’Orme des Merisiers Saint-Aubin, France2

The outstanding ability of YBa2Cu3O7−x (YBCO) films to carry high-currents at high-magnetic fields offers an unprecedented opportunity to be used in large-scale superconducting power applications and high-field magnets. In an essential need of high-performance and low-cost manufacturing, chemical-solution deposition (CSD) has become a very competitive cost-effective and scalable methodology to grow epitaxial YBCO-films [1]. However, their growth-rates are rather small (0.5-1 nm/s). For this purpose, we have developed a novel growth-approach, entitled, Transient Liquid Assisted Growth (TLAG) [2], which is able to combine CSD methodologies with ultra-fast growth-rates (100-1000 nm/s) by facilitating a non-equilibrium liquid-mediated approach. Critical current-densities up to 5 MA/cm2 at 77K are already realized in TLAG-CSD grown thin films, but in order to further improve the current carrying properties, understanding of initial nano-phases in pyrolysis process and fine-tuning of growth parameters are essential in thicker films. Therefore, the microstructure of multideposited pyrolyzed and grown YBCO films, investigated via high-resolution transmission electron microscopy (HR-TEM), scanning-TEM (STEM), electron-energy loss spectroscopy (EELS) and energy-dispersive X-ray spectroscopy (EDX), will be presented.

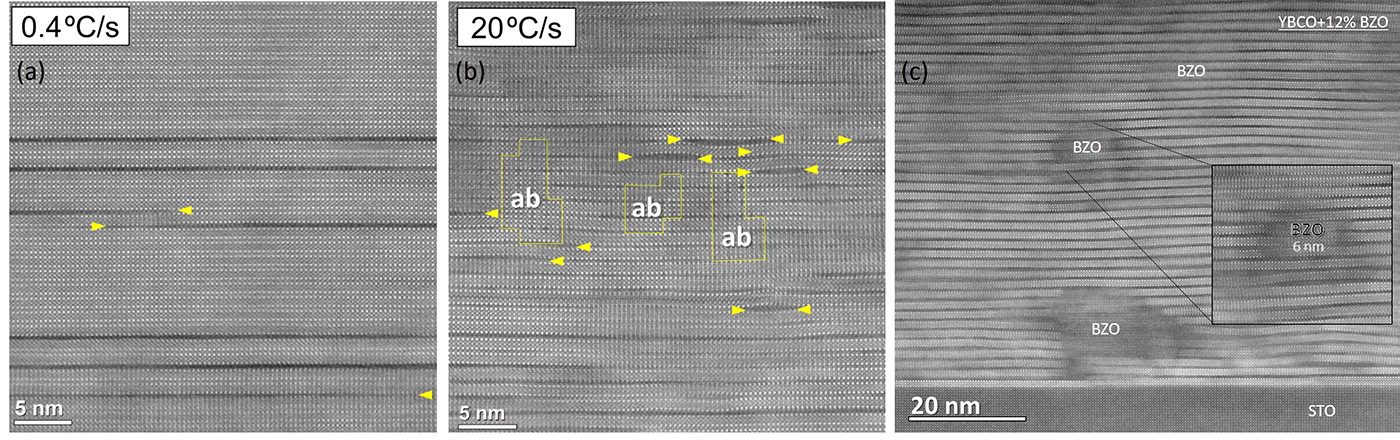

Furthermore, the critical current-density capabilities of high-temperature superconductors (HTS) are determined by its microstructure and it can be enhanced by the presence of well-controlled nano-defects inside the epitaxial superconducting matrix acting as vortex-pinning-centers. TLAG-CSD has demonstrated the growth of nanocomposites to increase flux-pinning at high magnetic-fields by incorporating pre-formed NPs to the metal-organic initial inks [2]. Therefore, using aberration-corrected STEM combined with high angle annular dark field (HAADF) and EELS, the detailed microstructure of grown TLAG-CSD YBCO films, nanocomposites, and coated-conductors, with a focus on new defects landscape at the atomic-level, secondary phases, and strain-effects, will be presented. Finally, the recent progress in TLAG-CSD films and nanocomposites, in terms of microstructure correlation with growth mechanisms and growth rate will be discussed.

[1] J. Gutierrez, A. et al., Nat. Mat., 6, 367 (2007)

[2] L. Soler et al, Nat. Commun., 11, 344 (2020)

Figure Caption: STEM-HAADF images of TLAG-CSD YBCO films indicating the different microstructures for a) 0.4 ºC/s, (b) 20º/s, highlighting the tunability of TLAG-CSD for vortex pinning, and (c) a 12% BaZrO3 (BZO) nanocomposite, where inset shows that BZO nanoparticles grow epitaxial with the YBCO matrix contrary to the other CSD processes [2].

Keywords: YBCO, TLAG-CSD, TEM, Superconductivity