AP1-2-INV

Test operation of 500 m /100 MW Ishikari high-temperature superconducting DC transmission line to demonstrate the required cost reduction and robustness for practical social applications

Nov. 29 10:30-11:00

*Noriyuki Inoue1,2, Noriko Chikumoto2, Hirofumi Watanabe2, Yuri Ivanov2, Tomoaki Hino2, Akio Sato1,3, Toru Sawamura1,4, Hisashi Yamamoto1,5, Katsunori Sumi1,2, Kiyoshi Okuno2, Osamu Motojima1,2

Ishikari Superconducting DC Power Transmission System1

Chubu University2

JFE Steel Corporation3

SAKURA internet Inc.4

JGC CORPORATION5

Superconducting DC transmission (SCDC) can reduce power losses during transmission to one-tenth of the losses occurring duringconventional AC transmission. Therefore, it is expected to be a key technology for achieving carbon neutrality (CN). The advantages of SCDC are its ability to transmit power over long distances at a low voltage and the compact geometry of superconducting cables. Owing to their compactness, it is possible to install underground cables that are robust against natural disasters, such as typhoons and earthquakes, at low costs and with negligible environmental impact. SCDC is expected to address problems such as insufficient capacities in existing transmission lines that may result from the future increase in renewable energy use. Thus, innovative power networks can be developed.

The social implementation of SCDC, however, may require further preliminary research and the creation of a new business model based on the resulting database. As the first step in this process, this paper describe the results of the Ishikari Line 1 restart test conducted in September 2021 to collect basic data for cost reduction and improved efficiency and to confirm the equipment integrity after approximately 6 years of shutdown. Based on these results, we aim to promote the social implementation of SCDC by constructing a database for the quantitative evaluation of reliability, safety, and cost.

The Ishikari Superconducting DC Power Transmission System (I-SPOT) was established in January 2014 as a Collaborative Innovation Partnership (CIP) under the authority of the Ministry of Economy, Trade, and Industry (METI). Its objective is to implement research activities on SCDC and related technologies, including design, construction, and performance demonstrations at large-scale facilities. The Ishikari SCDC demonstration test facility was constructed in 2013 in Ishikari, Hokkaido, and comprises the world’s longest class of 500 m (Line 1) and 1000 m (Line 2) cable systems. Based on a 4 year demonstration test conducted on Lines 1 and 2 of the SCDC system, it was confirmed that SCDC can reduce the transmission loss to one-tenth of conventional AC transmission system losses. A key technology for this reduction was a recently developed ultra-low-loss cryogenic pipe, which achieved a heat loss of less than 1 W/m along the cable.

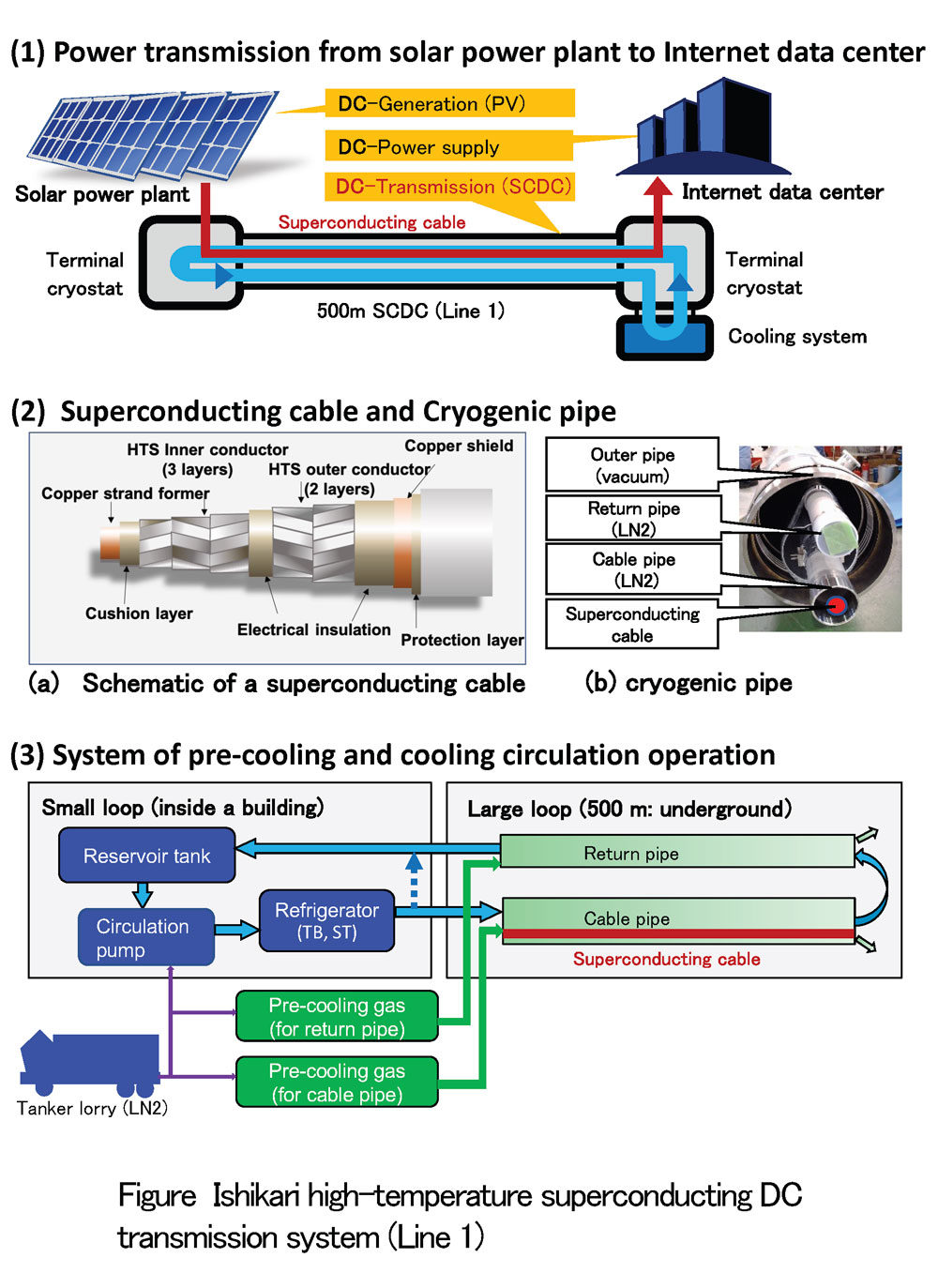

Using Line 1, which is a 500 m SCDC system (5 kA, 20 kV, 100 MW) installed underground, we successfully demonstrated the world's first power transmission from a solar power plant to an Internet data center in September 2015. After two comprehensive tests (cooling and energizing operations) in 2015, the operation of Line 1 was suspended for an extended period and was restarted in September 2021, with neither cooling nor energizing conducted, while a vacuum was maintained inside the cryogenic pipe. During the shutdown period, a strong earthquake occurred (2018 Hokkaido Eastern Iburi Earthquake, September 6, 2018, maximum intensity of 7), and the Ishikari area experienced an intensity of 5 Lower. The restart operation confirmed the integrity and robustness of the facility, which had experienced a major earthquake and was shut down for approximately 6 years.

The main components of Line 1 are the cooling, insulation and vacuum, electrical, and measurement and monitoring systems. The interior of the cryogenic pipe was vacuumed, and liquid nitrogen flowed through two inner pipes (cable and return pipes). A superconducting cable was installed inside the cable pipe. Terminal cryostats were installed at both ends of the cryogenic pipe, and measurement signals, such as power, liquid nitrogen refrigerant, superconducting cable, and current lead voltage, were transmitted across low and room temperatures.

The procedure for the restart test was as follows: (1) vacuum evacuation of the cryogenic pipe, (2) initial cooling of the cable and return pipes (flow of low-temperature nitrogen gas), (3) circulation of liquid nitrogen using a refrigerator and circulation pump, (4) conduction of cooling and circulation tests, as well as various electrical tests, and (5) following completion of all tests, an increase in the temperature to room temperature and termination of the entire operation. During the restart test, cooling circulation and electrical tests were conducted under various operating conditions in addition to the rated conditions.

The integrity and robustness of all system components, including the SCDC main unit, chiller, control equipment, vacuum system, and measurement system, were confirmed. For superconducting cables, our results confirmed that autonomous uniformity of the current distribution occurs at the connections. These results are useful for replacing the Peltier current leads with normal current leads. The integrity of the superconducting cable was tested in terms of its capacitance, insulation resistance, and DC withstand voltage. The superconducting state was maintained under the rated conditions, and the cable was energized in a stable manner. To improve the chiller operation efficiency, the overall system could be cooled using the turbo Brayton chiller alone; accordingly, partial load conditions that reduced the chiller efficiency could be observed. It was also demonstrated that SCDC can be operated by circulating liquid nitrogen at high temperatures and low flow rates. Optimization of the refrigerant conditions and high-efficiency operation of the refrigeration equipment are also possible.

These results suggest that, with appropriate maintenance, the SCDC system can sufficiently maintain normal operation characteristics for several decades in practical applications.

Keywords: High Temperature Superconductor (HTS), DC Transmission, long distance transmission, carbon neutral (CN)