AP10-6

Increment of levitation stability in the magnetic circuit design of the HTS magnetic bearing rotor

Dec. 1 16:30-16:50

*Rento Taniguchi1, Shuto Ishida1, Keigo Yagi1, Shunsuke Ohashi1

Department of Electrical and Electronic Engineering, Kansai university, Japan1

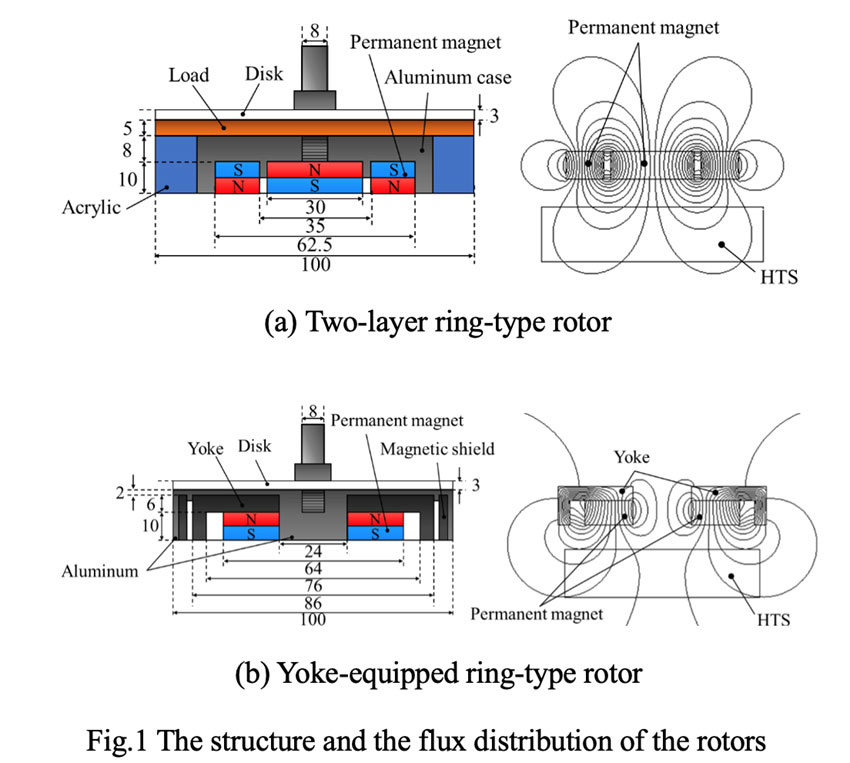

Magnetic levitation using the pinning force of a high-temperature superconductors (HTS) has the advantage which is stable levitation without control [1], [2]. The magnetic circuit design of the HTS magnetic bearing to increase pinning force is studied. The magnetic bearing system uses the HTS on the stator and the rotor on the rotor. The HTS bulk material is yttrium barium copper oxide. The HTS diameter is 80 [mm] and its thickness is 20 [mm]. The rotor is levitated by the pinning force of the HTS. The HTS is installed on the stainless stage, and the acrylic plate for a spacer is installed on the HTS. The rotor is set on the spacer, which is placed at the center of the HTS. Liquid nitrogen is poured into the stainless vessel until the HTS is immersed therein, and the HTS is retained in a magnetic field for 20 min (field cooling). Once cooling is complete, the spacer is removed and the rotor is levitated. Fig.1 shows the structure of two layer ring-type rotor, yoke-equipped ring-type rotor and the magnetic flux distribution of that. The neodymium magnet is used for the rotors. The two-layer ring-type rotor comprises a cylindrical and a ring-type permanent magnet, and the flux at the top side dose not interlink sufficiently with the HTS[3]-[5]. The yoke-equipped ring-type rotor is introduced to increase the flux-use rate to use the flux at the top side. By concentrating the flux of the rotor on the HTS, the pinning force of this rotor increases. In designing the magnetic circuit of the rotors, the flux interlinked with the HTS surface increased and focused to the outer side of the HTS. The permanent magnet volumes of the two-layer ring-type rotor and the yoke-equipped ring-type rotor are almost the same. The experiment is studied the levitation gap g=8,10 [mm]. When the levitation gap is 8 [mm], the total flux of the yoke-equipped ring-type rotor interlinked with the HTS surface increases by 54.9% compared with the two- layer ring-type rotor. The levitation force increases by 24.4% compared with that one. The guidance force increases by 69.5% compared with that one. When the levitation gap is 10 [mm], the total flux of the yoke-equipped ring-type rotor interlinked with the HTS surface increases by 68.4% compared with that one. The levitation force increases by 24.8% compared with that one. The guidance force increases by 62.6% compared with that one. By equipping the yoke to the rotor, the total flux increases, and the pinning force also increases. As the result, the maximum amplitude is decreased at the resonance point in the rotational characteristics, and the rotor stability increases. When the levitation gap is 8 [mm], the maximum amplitude of the yoke- equipped ring-type rotor decrease by 61.2% compared with that one. When the levitation gap is 10[mm], the maximum amplitude of the yoke-equipped ring-type rotor decrease by 59.0% compared with that one. This is because by concentrating the flux on the outer side of the HTS, the force that suppresses vibration during resonance has increased. By improving the magnetic circuit, the levitation force, the guidance force, and the rotational characteristics of the yoke- equipped ring- type rotor are improved. As the result, the stability of the rotor has improved.

References

[1] F. C. MOON, “SUPERCONDUCTING LEVITATION”, JOHN WILEY & SONS, NEW YORK, (1994)

[2] J. Hull, M. Murakami, “Apprications of bulk high temperture superconductors”, in Proc of IEEE, vol. 92, no. 10, October 2004, pp1705-1718

[3] S. Sakai, K. Oguni, S. Ohashi, “Effect of the magnetic configuration on the rotational motion in the attractive type HTS-permanent magnet hybrid bearing”, IEEE Trans on Applied Superconductivity, vol. 26, no.4, 3601204, June 2016.

[4] T. Minami, S. Sakai, S. Ohashi, “Improvement of stability against vibration at the mechanical resonance in attractive type HTS permanent hybrid magnet bearing.”, 2016 IEEE Region 10 Conference (TENCON2016), 16657805, 2016, pp3294-3297.

[5] S. Takimura, T. Arai., T. Minami, S. Ohashi, “Basic characteristics of the yoke equipped rotors in the magnetic bearing using HTS pinning effect”, IEEE Xplore Digital Library IEEE, 12th International Symposium on Linear Dives for Industry Applications (LDIA2019), 8770991, 2019.

Keywords: HTS, Pinning force, Magnetic bearing, Permanent magnet