WB2-3

Characteristics of voltage appeared at the current feeder of high-temperature superconducting WISE conductor and its improvement

Nov. 29 14:40-14:55

*Yoshiro Narushima1,2, Diego Garfias-Davalos2, Yuta Onodera1, Shinji Hamaguchi1, Hirotaka Chikaraishi1, Nagato Yanagi1,2, Tomosumi Baba1, Junichi Miyazawa1,2

National Institute for Fusion Science, 322-6 Oroshi-cho, Toki, Gifu, 509-5292, Japan1

The Graduate University for Advanced Studies, SOKENDAI, 322-6 Oroshi-cho, Toki, Gifu, 509-5292, Japan2

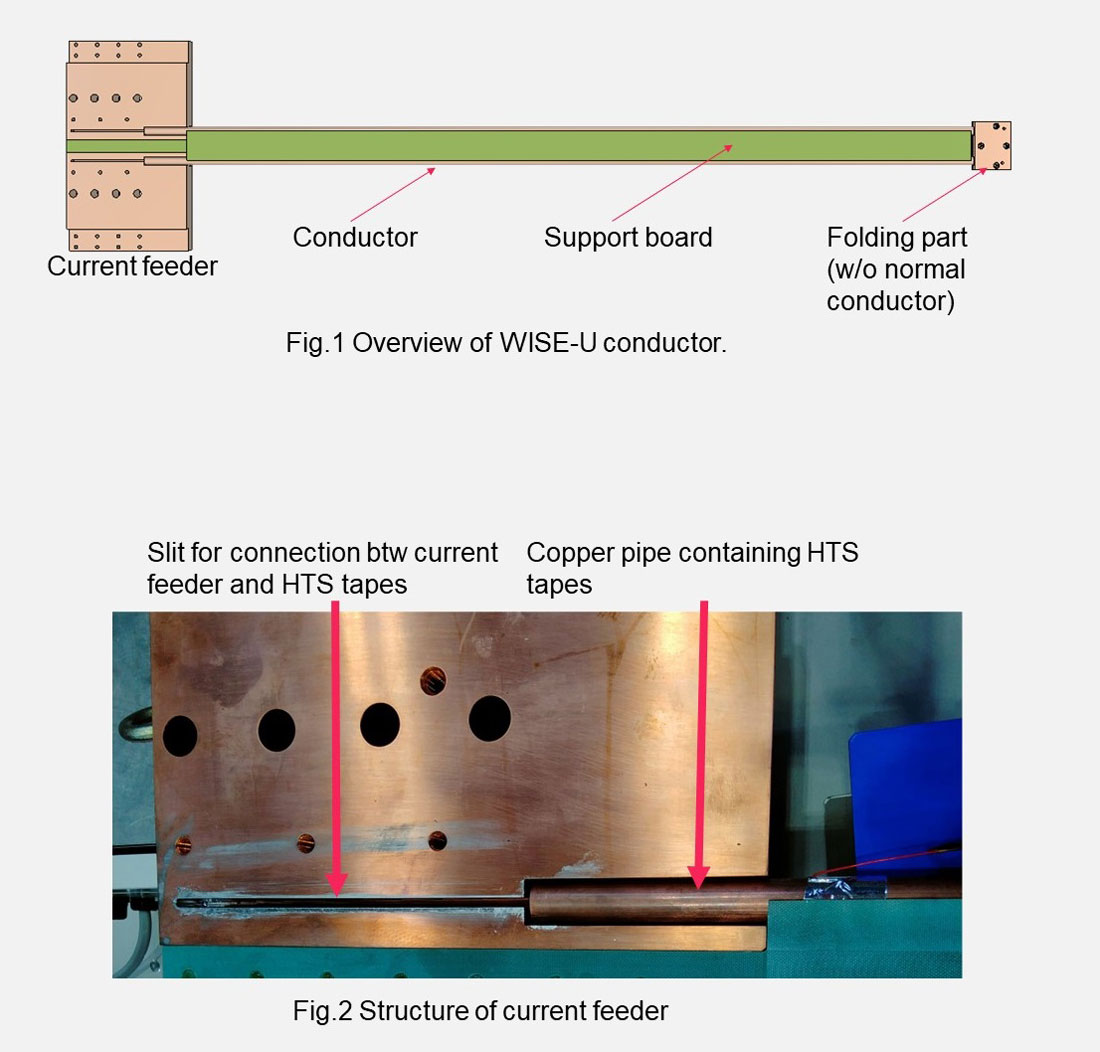

The HTS (high-temperature superconducting) conductor is a feasible candidate for constructing magnets for the next-generation fusion devices because of its higher critical current in a high magnetic field. A new concept of the HTS-WISE (Wound and Impregnated Stacked Elastic tapes) conductor has been studied aiming to apply the fusion reactor magnet. Here, the WISE-U conductor is composed of stacked thirty REBCO tapes (10 mm width, 65 μm thickness, Ic = 370 A @77 K, s.f.) wrapped by a stainless-steel coil tube which is inserted into the metal pipe. The 4 m-long REBCO tapes are folded with a radius of curvature of 35 mm in a hairpin-like structure as shown in Fig. 1. A low-melting-point metal U-Alloy 60 whose melting point is 60°C is poured into the pipe for impregnation to make the non-insulation conductor. The REBCO tapes and the current feeder made of oxygen-free copper were also impregnated with the U-Alloy 60 to connect (Fig.2). This fabrication method has the advantage of being easier to fabricate than the technique of connecting each tape using indium foil. The energization test results showed that a maximum current value of 16.9 kA was recorded at B = 5 T and T = 30 K, however, a burnout occurred in the current feeder before the critical current was determined. Then, the modified WISE conductor has been designed and tested which showed a maximum of 19.7kA was reached in the self-field and 20K. However, burnout still occurred in the current feeder section. In those experiments, the superconductor part has not been damaged at all. If this burnout had been avoided, a higher current-carrying capacity could have been obtained. Identifying the cause of burnout and improving the current feeder is required. The voltage behavior of current feeders and improvement ideas will be presented in detail.

Keywords: HTS, ReBCO, Helical fusion reactor, WISE