WB4-8

Growth mechanism of BaMO3-doped REBa2Cu3Oy thin films by Vapor-Liquid-Solid technique simulated by Monte Carlo simulation

Nov. 30 12:15-12:30

*Tomonori Arita1, Yusuke Ichino2, Yutaka Yoshida1

Nagoya University, Japan1

Aichi Institute of Technology, Japan2

Introduction

We have introduced the vapor-liquid-solid (VLS) growth technique to fabricate REBa2Cu3Oy (REBCO, RE= rare earth: Y, Sm, etc.) thin films [1]. VLS growth technique is a solution growth method, which can fabricate REBCO thin films with a higher deposition rate and good crystalline orientation than films prepared by conventional pulsed laser deposition (PLD) method, which is a vapor phase epitaxy. To improve Jc in magnetic field, however BaHfO3 (BHO)-doped YBCO films were grown by the VLS growth technique, the films included two regions, one was a region without BHO and the other was a region consisting of segregated BHO [1]. Self-organization process of BMO nanostructures in REBCO films, which were prepared by vapor phase epitaxy, has been investigated by both experimental and computational approaches. [2, 3]. However, there are few reports on a mechanism of BMO self-organization in the VLS growth technique. To understand the mechanism, we have been developing a crystal growth simulation code concerning to VLS growth technique. In this study, we performed the simulations at various substrate temperatures (Ts) and BMO contents to understand the crystal growth of BMO-doped REBCO thin films and the behavior of BMO molecules in a liquid phase in the VLS growth technique.

Simulation

In this study, we used a three-dimensional Monte Carlo simulation for crystal growth. This simulation takes into account solvation energies of REBCO and BMO in a liquid phase, to simulate a solution growth. The simulations were performed at T·s = 1113 ~ 1313 K and BMO contents of 0 ~ 5 vol. % to investigate the effects of Ts and BMO contents on BMO nanostructures and growth of REBCO thin films.

Results and discussion

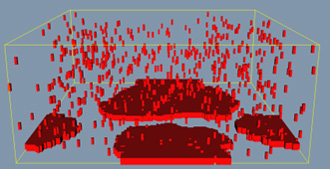

Fig. 1 shows the result at Ts = 1113 K and 0 vol. % BMO. REBCO and BMO unit cells are expressed using simple cubes with the side length of 0.4 nm, and the computational space has 48 nm along ab-plane and 20 nm along c-axis. The bottom of the space is the substrate made of a single crystalline REBCO, and the top is the surface of liquid phase. From the figure, REBCO unit cells are diffusing in the liquid phase and are growing into 2D islands on the substrate surface. We will report the results of the different Ts and BMO contents, and the difference from vapor phase epitaxy.

References

[1]. T. Ito, et al., “Effect of Surface Liquid Layer during Film Growth On Morphology of BaHfO3 in YBa2Cu3Oy Coated Conductors Fabricated by Pulsed Laser Deposition”IEEE. Trans. Appl. Supercond., vol. 31, no. 5, Aug. 2021, Art. No. 6601205.

[2]. S. Miura, et al., “Determinant for Self-Organization of BaMO3 Nanorods Included in Vapor-Phase-Grown REBa2Cu3Oy Films” IEEE. Trans. Appl. Supercond., vol. 25, no. 3, Jun. 2015, Art. No. 6604506.

[3]. Y. Ichino, et al., “Three-dimensional Monte Carlo simulation of nanorod self-organization in REBa2Cu3Oy thin films grown by vapor phase epitaxy” Jpn. J. Appl. Phys. 56 015601.

Acknowledgements

This work was partly supported by JSPS-KAKENHI(20H02682, 19K22154),REFEC(R-02223), and NEDO.

Figure

Fig. Snapshot of VLS-grown REBCO at 1113 K and 0 vol.% BMO using the Monte Carlo simulation.The size of the box is 48×48×20 nm. REBCO unit cells are diffusing in the liquid phase and are growing into 2D islands on the substrate.

Keywords: monte carlo simulation, REBCO, Vapor-Liquid-Solid technique