WB9-6

Transmission Electron Microscopy Analysis of High Current Density REBCO Superconducting Thin Films and Coated Conductors Grown by Ultrafast Transient Liquid Assisted Growth (TLAG)

Dec. 1 18:25-18:40

*Kapil Gupta1, Lavinia Saltarelli1, Albert Queraltó1, Roger Guzmán1, Laia Soler1, Júlia Jareño1, Juri Banchewski1, Silvia Rasi1, Diana Garcia1, Valentina Roxana Vlad1, Aiswarya Kethamkuzhi1, Joffre Gutierrez1, Susagna Ricart1, Cristian Mocuta2, Xavier Obradors1, Teresa Puig1

Institut de Ciència de Materials de Barcelona (ICMAB-CSIC), Campus UAB, 08193 Bellaterra, Barcelona, Spain1

Synchrotron SOLEIL, L’Orme des Merisiers Saint-Aubin, BP 48, 91192 Gif-sur-Yvette, France2

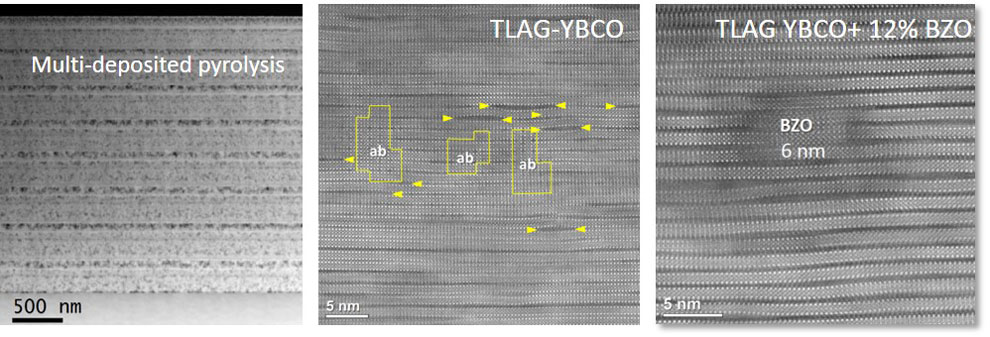

Among high temperature superconductors (HTS), cuprate superconductors (REBa2Cu3O7-δ (REBCO, RE = rare earth)) have garnered most research efforts in large-scale superconducting power applications and high field magnets due to their high critical temperature (~ 92 K) and outstanding ability to carry high critical currents at high magnetic fields owing to the high irreversibility line. A limiting factor in its implementation is the need of high performance/low-cost manufacturing of epitaxial films, for which, chemical-solution deposition (CSD) has become a very competitive cost-effective and scalable methodology [1]. However, slow growth rates (0.5-1 nm/s) are one of the main obstacles for CSD to become a high through-put process. For this purpose, we have developed a novel fluorine-free growth approach, entitled, Transient Liquid Assisted Growth (TLAG) [2,3], which is able to combine CSD methodologies with ultra-fast growth rates (100-1000 nm/s) by facilitating a non-equilibrium liquid-mediated approach. Critical current densities up to 5 MA/cm2 at 77K are already realized in TLAG-CSD grown thin films, but in order to further improve the current carrying properties, understanding of initial nano precursor phases in the pyrolysis process and fine tuning of growth parameters are essential to define a robust process and thicker REBCO layers [4]. Therefore, the microstructure of multi-deposited pyrolyzed and grown YBCO films, investigated via high-resolution transmission electron microscopy (HR-TEM), scanning transmission electron microscopy (STEM), electron-energy loss spectroscopy (EELS) and energy-dispersive X-ray spectroscopy (EDX), will be presented. In addition, a phenomenon of re-orientation of homogeneous to c-axis heterogeneous epitaxial growth of YBCO, observed during TLAG, will also be discussed.

Furthermore, the control over the YBCO film microstructure is essential to enhance the critical current-density capabilities. This can be achieved by the presence of well-controlled nano-defects inside the epitaxial superconducting matrix acting as vortex-pinning-centers. We found that the microstructure of pristine YBCO films could be tuned significantly via TLAG-CSD by optimizing different growth parameters. Besides, the addition of secondary phase nano-inclusions can also increase flux-pinning at high fields by incorporating pre-formed nanoparticles to the metal-organic inks [2]. Therefore, the detailed microstructure of REBCO films, REBCO nanocomposites, and coated conductors with varying growth parameters on different substrates investigated via HR-TEM, EELS, and using aberration-corrected STEM combined with high-angle annular dark field (HAADF), will be discussed in detail. Additionally, the capability of TLAG to augment other physical growth processes (e.g, pulsed laser deposition, PLD) and provide growth rates of more than two orders of magnitude higher than standard PLD growth of REBCO films has been attained [5], so, its microstructural study will also be discussed.

[1] J. Gutierrez, A. et al., Nat. Mat., 6, 367 (2007)

[2] L. Soler et al, Nat. Commun., 11, 344 (2020)

[3] S. Rasi et al, Adv Sci, 2203834 (2022)

[4] L. Saltarelli et al, (submitted)

[5] A. Queralto et al (submitted)

Keywords: REBCO, TLAG-CSD, TEM, Superconductivity